Our Mission

In times where peri-implantitis cases are surging, as evidenced by meta-analyses and discourse at congresses worldwide, we at Patent™ proudly offer a tooth replacement solution that opposes this alarming trend. Our team consists of dedicated and forward-thinking professionals who assist dentists across Europe with first-rate personal support in eliminating peri-implantitis from daily practice, guided by our vision of "Implant Dentistry Without Peri-Implantitis”.

Our Mission

Dentistry is constantly evolving. Despite this, implant success is often still measured using outdated criteria established in the 1990s. What was once considered a treatment success may now be regarded as a failure in view of the advancements made possible by cutting-edge technologies like Patent™. With a scientifically established ability to maintain overall tissue health and avoid implant fractures and peri-implantitis after well over ten years, Patent™ has been proved to raise the bar of what’s achievable with dental implants, demonstrating that it’s about time we redefined success and set a new standard.

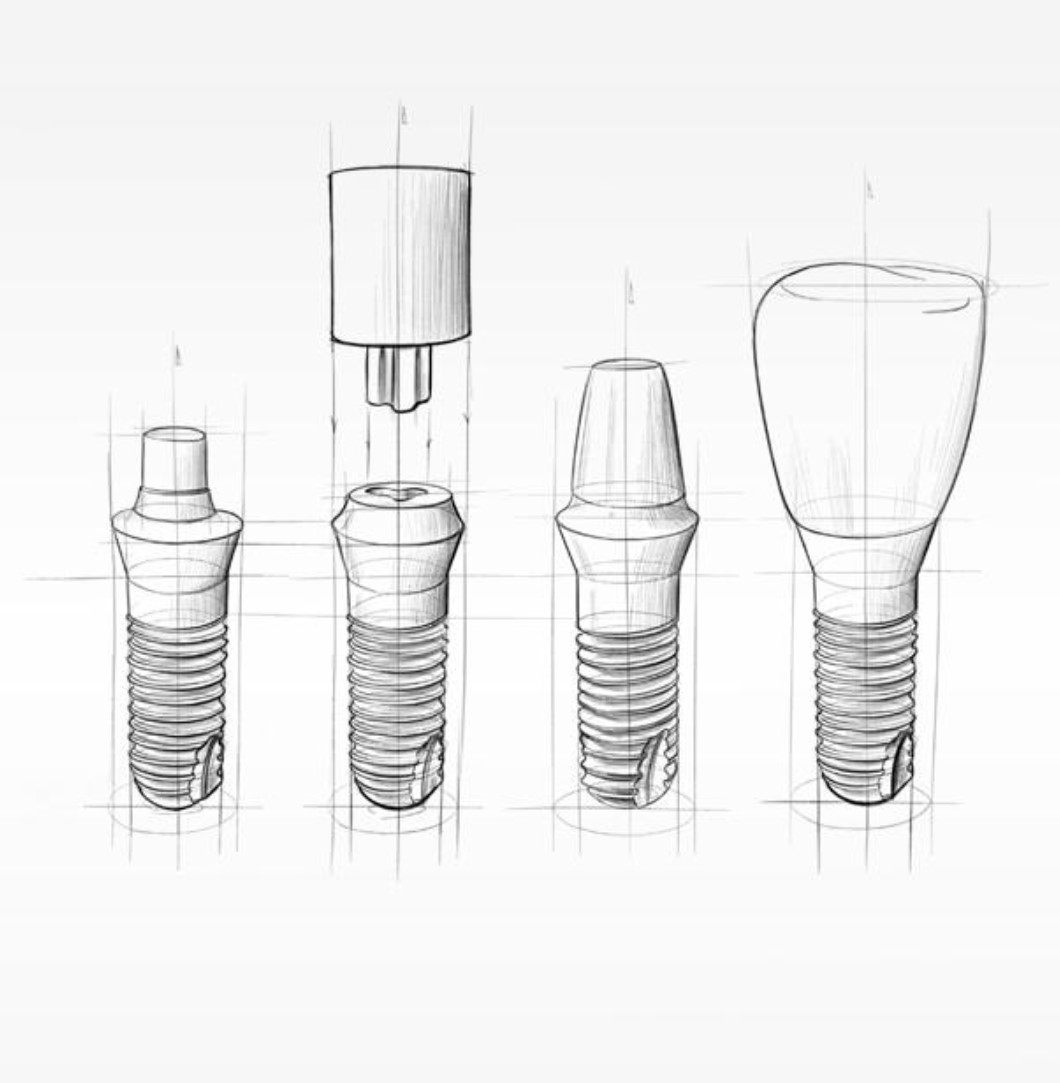

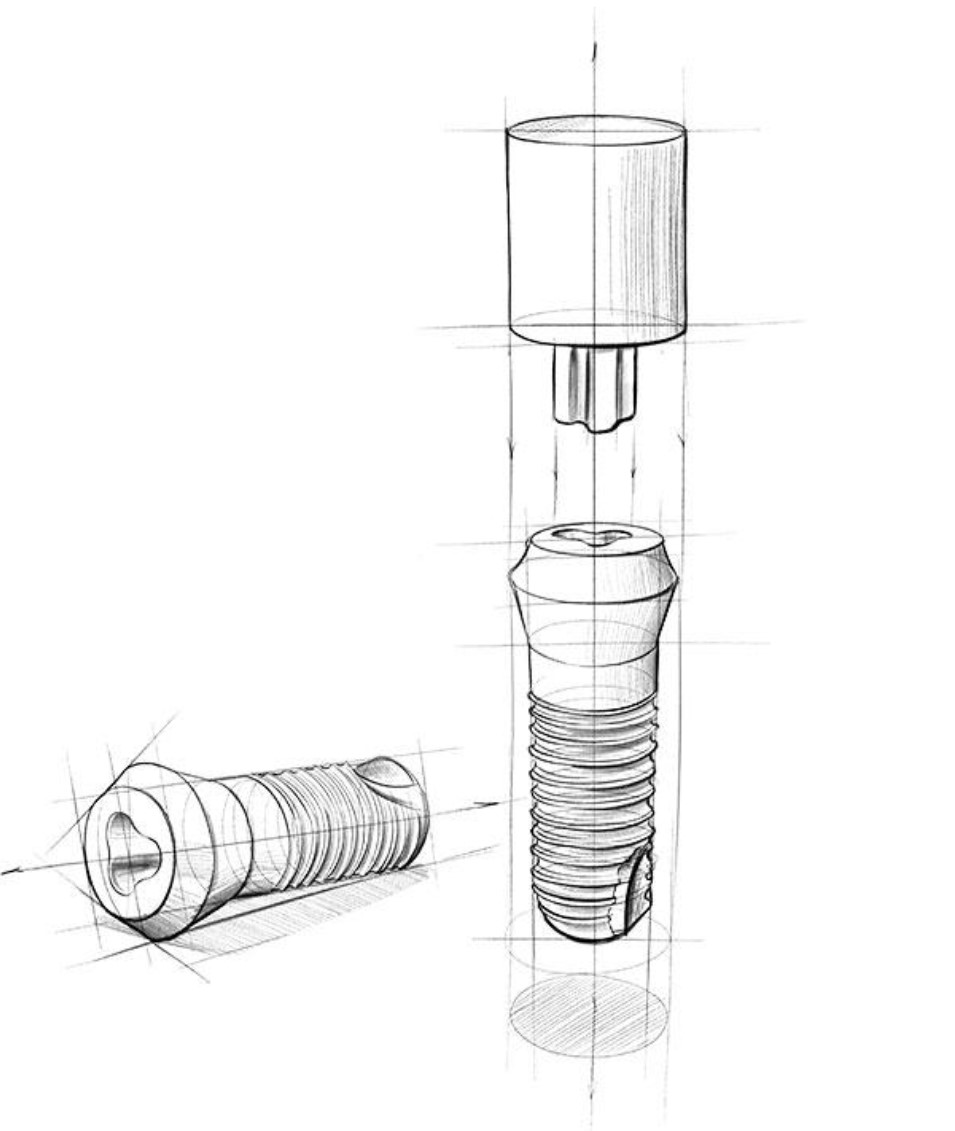

Patented Production

Zirconia implant production revolutionized: Only the patented process developed for the manufacture of Patent™ creates the surface topography necessary for predictable osseointegration and next-level soft-tissue attachment while maximizing the implant’s long-term strength. Employing this ingenious method, Zircon Medical is achieving mastery of the intricate material of zirconia in two exclusive production plants in Germany.

Patented Production

Zirconia implant production revolutionized: Only the patented process developed for the manufacture of Patent™ creates the surface topography necessary for predictable osseointegration and next-level soft-tissue attachment while maximizing the implant’s long-term strength. Employing this ingenious method, Zircon Medical is achieving mastery of the intricate material of zirconia in two exclusive production plants in Germany.

History

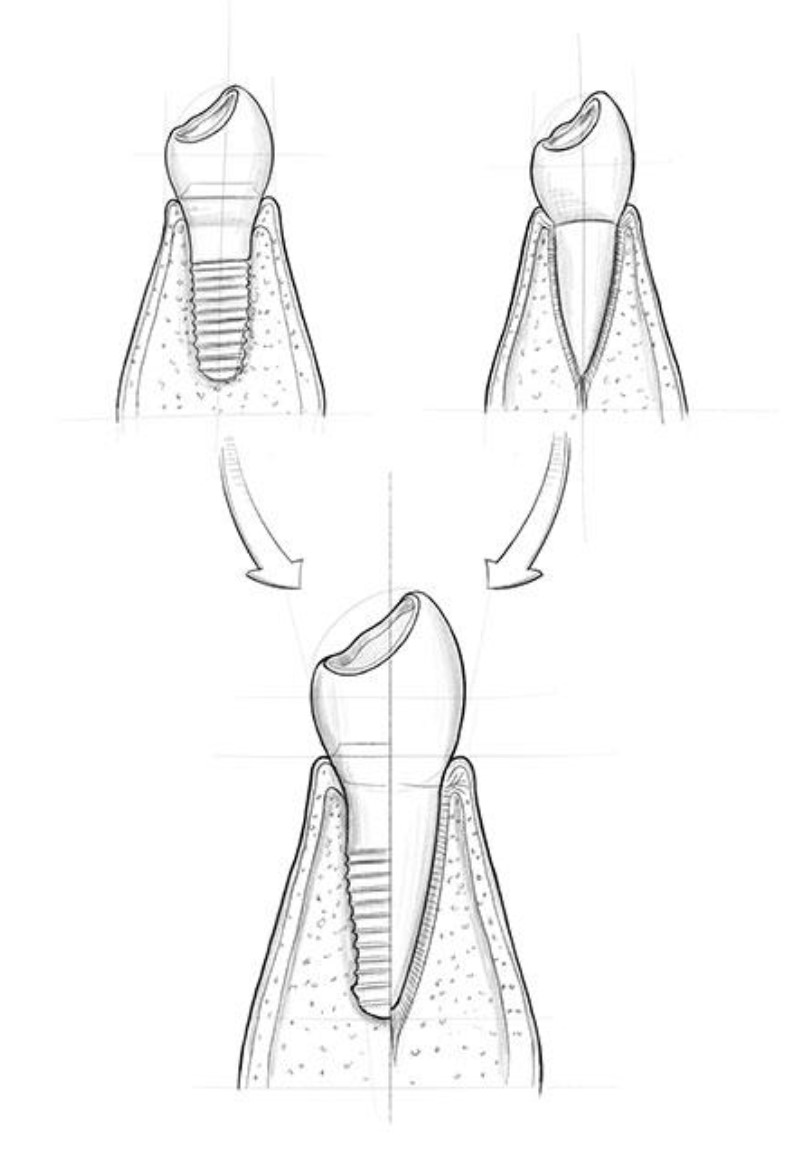

Over 20 years ago, two distinguished dentists with backgrounds in engineering set out to eliminate implant complications common at the time. Drawing inspiration from the natural tooth, they developed ZV3, a tooth replacement solution able to facilitate long-term oral health. With its acquisition by Zircon Medical in 2019, the brand name was changed to Patent™. Today, data from over 18 years of clinical use and independent long-term studies prove: Patent™ is the healthiest long-term tooth replacement worldwide.

History

Over 20 years ago, two distinguished dentists with backgrounds in engineering set out to eliminate implant complications common at the time. Drawing inspiration from the natural tooth, they developed ZV3, a tooth replacement solution able to facilitate long-term oral health. With its acquisition by Zircon Medical in 2019, the brand name was changed to Patent™. Today, data from over 18 years of clinical use and independent long-term studies prove: Patent™ is the healthiest long-term tooth replacement worldwide.

Team

With a dedicated team of over 40 specialists from various industries, Zircon Medical operates all over Europe and is continuously expanding its business reach. Our ambitious Zircon Medical employees are all driven by one goal: improving tooth loss patients’ oral health, well-being and quality of life with purposefully developed, scientifically backed and long-term functional tooth replacement solutions.

Team

With a dedicated team of over 40 specialists from various industries, Zircon Medical operates all over Europe and is continuously expanding its business reach. Our ambitious Zircon Medical employees are all driven by one goal: improving tooth loss patients’ oral health, well-being and quality of life with purposefully developed, scientifically backed and long-term functional tooth replacement solutions.

First Long-Term Study on Two-Piece Zirconia Implants

Download the Scientific Summary & the Patent™ Intro Guide!

First Long-Term Study

on Two-Piece Zirconia Implants

Download the Scientific Summary & the Patent™ Intro Guide!